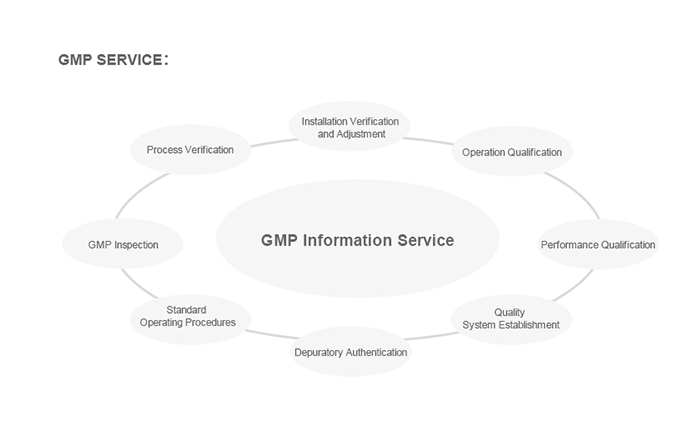

Provide full-process services including system design consulting, system equipment, GMP verification consulting, upgrading and renovation, operation and maintenance, etc.

Compliance with regulatory standards, continuous safe and stable operation of equipment, convenient operation, and exquisite workmanship;

Timely delivery, fast installation, and efficient input

Long service life, safe, stable and efficient operation during the service life;

Cost saving in multiple dimensions such as investment, operation, management, maintenance, and risk;

Pre-sale, in-sale, after-sale service, rapid response, standardized service.

• Design review

• Joint review of drawings

• Technical confirmation

• Participate in the entire installation process

• Provide system technical data

• Pass the exam and take the job

• Update and upgrade training materials

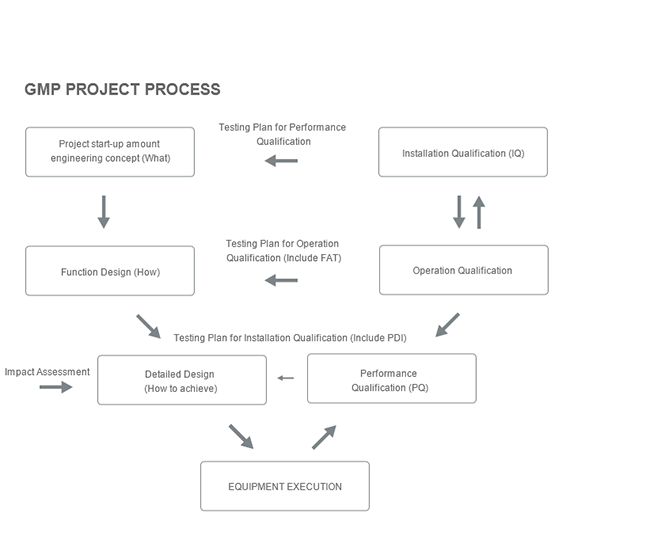

• Design confirmation (DQ)

• Factory Acceptance Test (FAT)

• Installation Qualification (IQ)

• Operational Qualification (OQ)

• Site Acceptance Test (SAT)

• Performance Qualification (PQ)

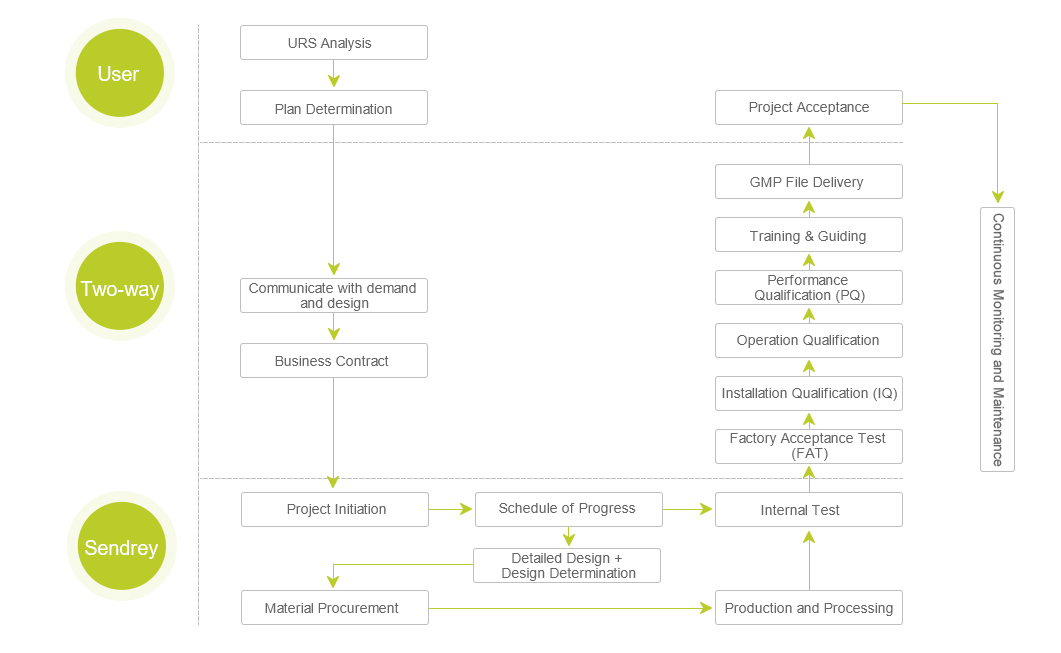

URS Requirement Analysis

Project evaluation

Project planning

Project Design

Design confirmation

Installation/debugging

Verification Service

Training services

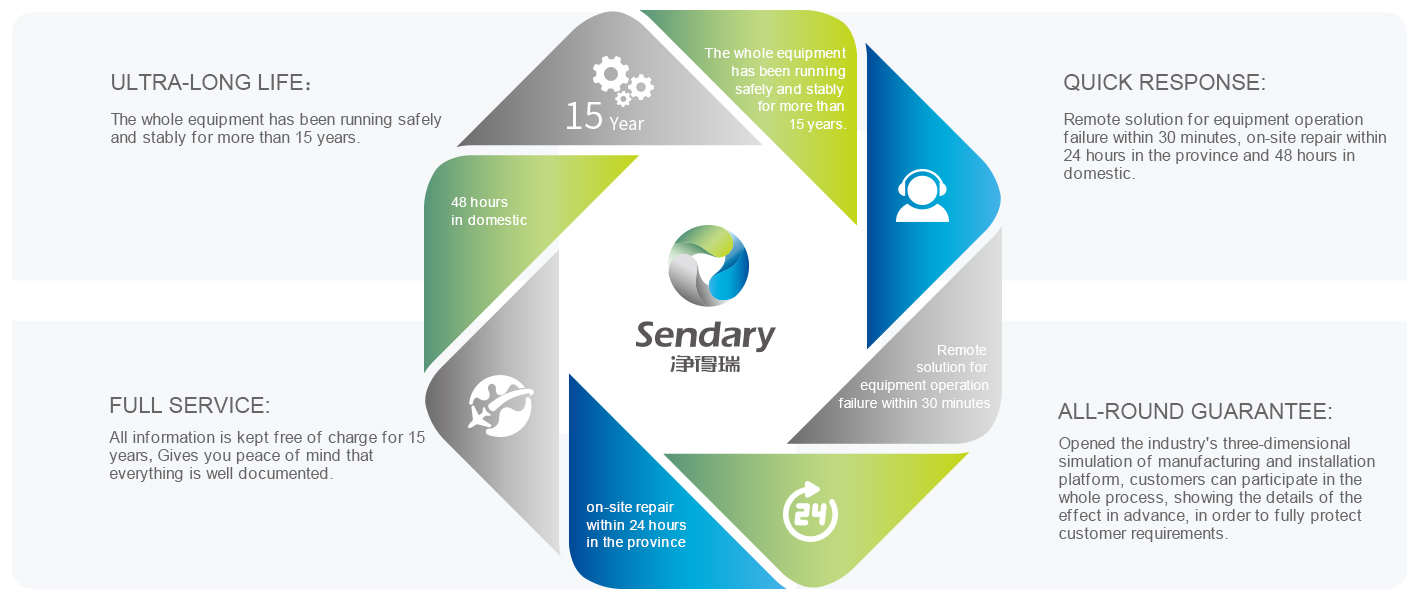

Rapid response, providing solutions within 30 minutes

Long-term service

Free storage of all materials for 15 years

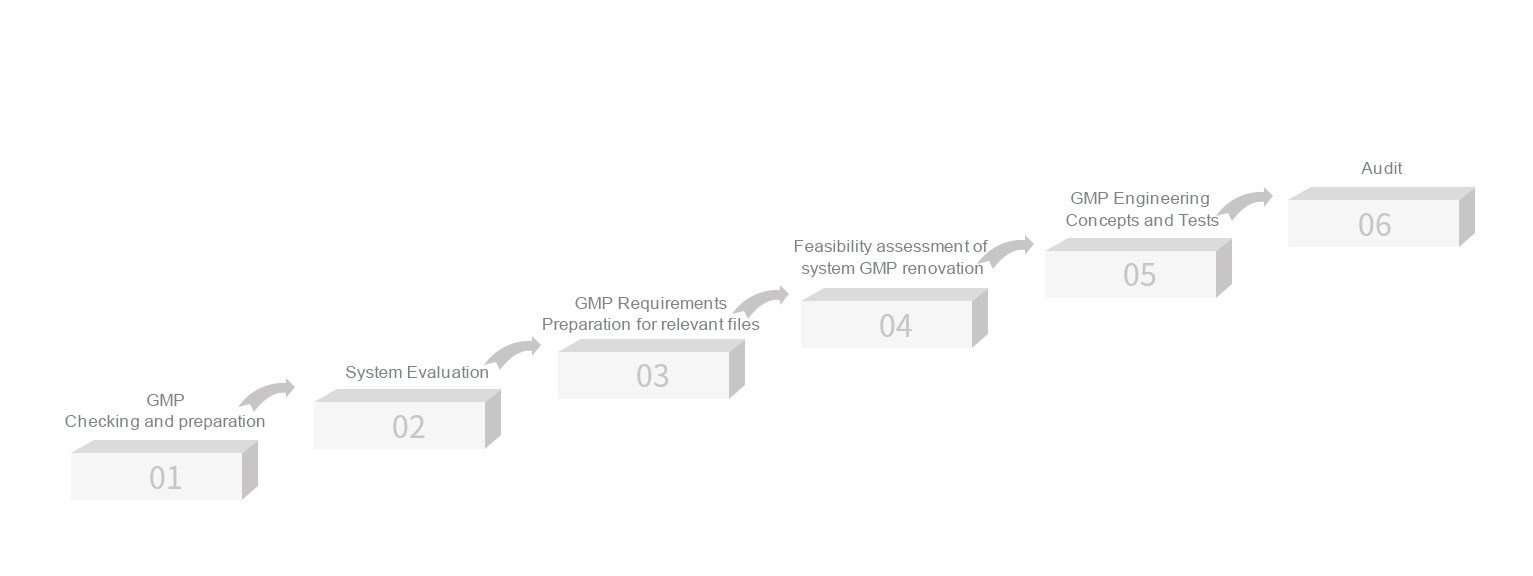

Provide customers with full life cycle services such as demand analysis, project evaluation, project planning, project design, verification services, project management, training, etc., meet personalized needs for verification services and system upgrades and renovations, and actively follow up on system usage through regular visits and on-site inspections to reduce the occurrence of system failures caused by improper maintenance and management, help customers establish a systematic management system, and become an advocate and promoter of a benchmarking service system in the industry.

• 3D design modular installation, guided by customer needs, customer participation in the whole process

• Sanitary piping engineering

• Non-standard atmospheric pressure vessels and pressure vessels

• Water treatment design and engineering

• Pure water and purified water treatment equipment system

• Multi-effect distiller, pure steam generator system

• Storage tanks, storage equipment

•Filter series

• Manufacturing of non-standard atmospheric and pressure vessels

• Installation of sanitary pipelines

• Installation of water treatment system equipment

• Allocation and installation of online disinfection system

• Installation of online cleaning system

• Training of operators

• Provision of validation templates

• Performance verification of equipment

• Periodic follow-up and return visits to equipment

• More than 10 years of experience in standardized design, manufacturing, research and development, and service of water systems

• Project experience and service capabilities of world top 500 benchmarking enterprises

Provide design and solutions that suit your needs based on your situation

The process of root-specific program customization is a continuous evolution from rough to refined, from vague to clear, and from abstract to concrete.

Key steps

Key parameters

Consideration of details

Product selection

Quality risk control

Balance with investment

Operation safety

discipline authenticity

Behavior tracking

Provide full-process services including system design consulting, system equipment, GMP verification consulting, upgrading and renovation, operation and maintenance, etc.

Provide GMP, FDA verification consulting and system DQ, FAT, IQ, QQ, SAT, PQ verification data

Pre-sale: URS demand analysis

During sale: design, installation, debugging, verification, training

After-sales: rapid response, long-term service

Comprehensive understanding of customer needs for product specifications, product processes, system configurations, etc. Tailored design

![]() Provide complete GMP system validation documents.Professional validation services throughout the project;

Provide complete GMP system validation documents.Professional validation services throughout the project;

>Free installation provides users with all the necessary conditions and work support for FAT testing;

>Provide users with free DQ, FAT, SAT, Q, OQ, PQ verification documents required for equipment;;

![]() International standards, in line with the requirements of the Chinese Pharmacopoeia, the European Pharmacopoeia, the British Pharmacopoeia, FDA, etc.;;

International standards, in line with the requirements of the Chinese Pharmacopoeia, the European Pharmacopoeia, the British Pharmacopoeia, FDA, etc.;;

![]() Striving for rich experience can avoid unnecessary design defects for you;

Striving for rich experience can avoid unnecessary design defects for you;

![]() High efficiency work can shorten the project cycle for you;

High efficiency work can shorten the project cycle for you;

>Provide users with guidance and related technical services during the installation of equipment for free;

>Provide free on-site equipment debugging for users to ensure that the equipment quality and related technologies meet contract requirements until the user completes SAT well acceptance and delivery for use;

>Free technical operator training for users until they are familiar with equipment and process technology and have the ability to independently operate, maintain, and repair the equipment (establish and provide SOP documents for customers)。

1. Train 1-2 equipment operation and management personnel to participate in the entire process of on-site installation to ensure that operators fully understand the equipment process principles.

2. Provide systematic technical information documents and comprehensive training, guide the completion of standardized operation procedures (SOP), establish operational inspection processes and systems.

3. After training, both practical and theoretical examinations will be conducted. A score of 90 in theory and 100 in practical operation is considered as passing the examination. Only those who pass the examination can take up their posts.

4. Provide updates and upgrades of equipment technical data and training materials as needed.

5. According to the operation and management personnel's use of equipment, they can receive targeted refresher training at Kerui Company.

1. After receiving the notification of equipment failure maintenance, propose a solution within 30 minutes and provide on-site service within 72 hours.

2. The equipment design, manufacturing, verification, and operation data are carefully preserved for 15 years, and a customer-specific file is established for easy access at any time, enabling traceability for equipment managers.

3. Set up a customer file management center,where after sales professionals can update。

4. After-sales professionals proactively conduct telephone follow-ups, record relevant data, and professional engineers review the data.If there are any issues, they will communicate and resolve them in a timely manner, and provide methods to reduce operating costs, reminders on maintenance and consumables replacement, and other related matters at any time.

5. The equipment is provided with vulnerable spare parts, and the company's warehouse is well stocked with commonly used consumables and accessories.Maintenance parts and materials are provided to the site for problem handling in the first time, and commonly used consumables and accessories are delivered to the site within 5-7 days.